Cold Aisle Containment Systems

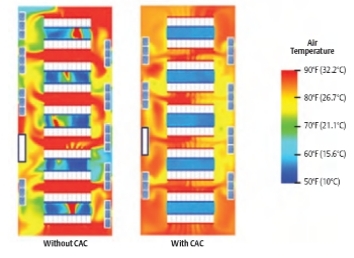

Reduce energy consumption with cold aisle containment by eliminating the mixing of hot and cold air

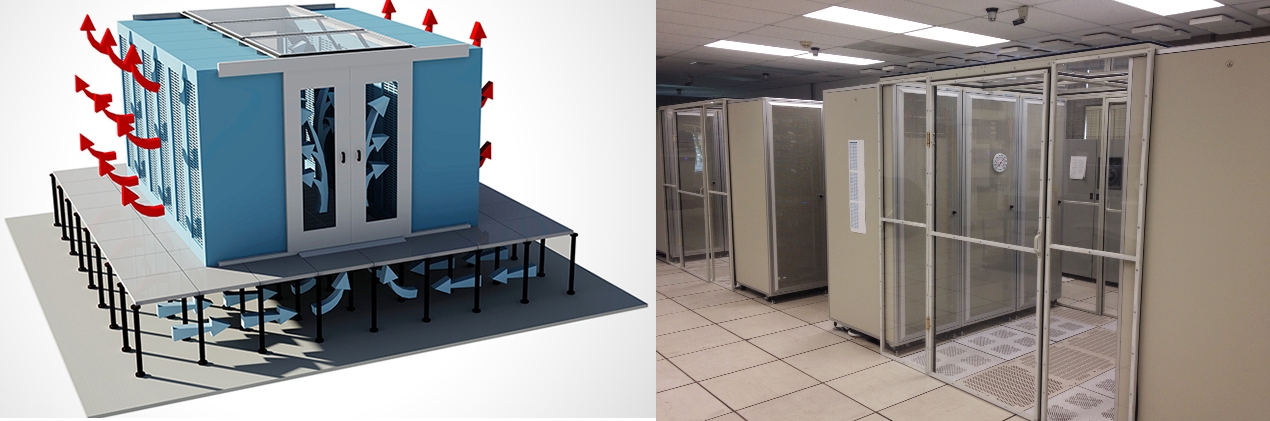

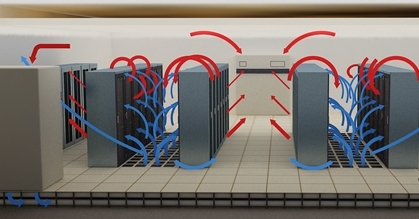

Cold Aisle Containment (CAC) Solution isolates a rooms cold air supply and confines it to an entirely closed off area targeted at cooling IT equipment instead of the room. With the fronts of cabinets facing each other as they would in a typical cold aisle design, the addition of doors on each end of the aisle and ceiling panels across those adjacent cabinet rows creates a complete segregation of hot and cold air.

Cold Aisle Containment-Advantages

It increases the cooling capacity and energy efficiency of the cooling unit ensuring that the return air temperature to the cooling unit is high. Second, the increased capacity, together with the separation of hot and cold air, makes it possible to cool higher heat loads per rack.

Additionally, with hotter air returning to the cooling coil, the cooling capacity available for cooling the sensible heat generated by the electronic equipment is increased. Under these conditions the cool supply air temperature is almost always above the dew point. Consequently, there is minimal moisture removal (latent cooling), which saves energy by allocating more of the total cooling capacity to dissipate the 100 percent sensible electronic heat load. The minimal latent cooling also increases the total energy efficiency because of less demand for re-humidification of the air.

Central Plant Energy Efficiency

Recommended server inlet temperatures range between 64.4 degree F and 80.6 degree F. Chillers typically produce chilled water around 45F degrees and inlet air around 58F degrees. This disparity exists, again, because of air mixing within the data center. As inlet air and exhaust air interact, the hope is the resulting inlet temperature falls somewhere in the recommended range.

Through containment, a user can eliminate this uncertainty. If he desires a 68F degree inlet temperature, perhaps he can achieve it with 58 degree F water. The warmer the water, the more efficient the chiller operates.

The current economic climate may delay an organizations ability to build a new data center. As a result, they will demand more uptime and more computing capacity from their existing facilities, while the industry encourages conservation and sustainability. Cold Aisle Containment proves an economical way to achieve both objectives

The premise of cold aisle containment, though simple, can improve cooling performance.

Data Center Hot Aisle/Cold Aisle Challenges

Even at minor heat loads, there are challenges associated with hot aisle and cold aisle. Some of them include:-

- Bypass air-The volume of cold supply air that enters the room but does not directly enter the IT equipment limits the precise delivery of cold air at the server intake.

- Hot air recirculation, where exhaust heat enters the cold aisle, either over the tops of racks or through open rack spaces, ensures that the cooling infrastructure must throw colder air at the equipment to offset this mixing.

- Hot air contamination prohibits the air handlers from receiving the warmest possible exhaust air, rendering their operation less efficient.

- Hot spots may persist as a result of all of the above

Data Center with Bypass Air problems (mixing of hot and cold air) A main cause of power loss.

As rack densities inevitably climb, the challenges above become more severe. The infrastructure struggles to deliver a sufficient volume of cool air to the equipment and to move exhaust air to the air handlers. As its forced to deliver colder air at a greater CFM, the cooling scheme consumes more energy from the fans through the pumps, down to the chiller. And even under minimal loads, the efficiency of these systems is suspect.

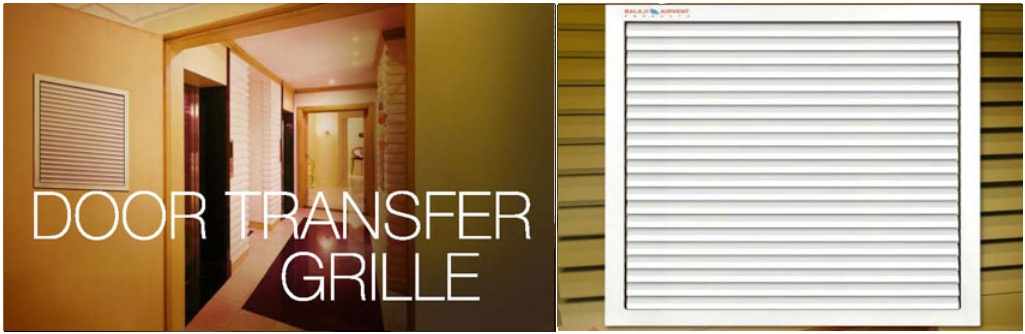

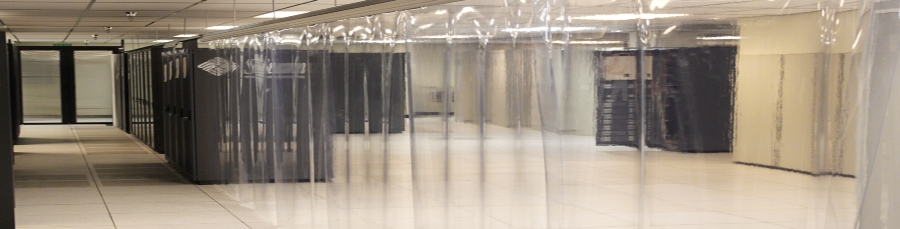

PVC Curtains

Cold Aisle Containment can be done using Flexible Polyvinyl Chloride (PVC) anti-static fire retardant PVC curtains which are hanged on either Aluminum/MS brackets fixed to ceiling or Assembled Aluminum support frame in overlapping manner for improved air sealing.

Aluminum Sliding Doors, Blanking Panels & Top Roof Panels

Easy to assemble Dual Sliding Door (Black anodized Aluminum Extruded Profiles & Transparent Acrylic Plexi Glass Fire retardant ULV-0 Sheets) is an ideal solution to end-of-row hot or cold aisle containment in any data center. Doors are available in standard sizes as well as custom sizes to fit under overhead obstructions or other sizing requirements. There are no obstructions on the floor of the aisle that could impede access of a person or trolley.

Easy to assemble Dual Sliding Door (Black anodized Aluminum Extruded Profiles & Transparent Acrylic Plexi Glass Fire retardant ULV-0 Sheets) is an ideal solution to end-of-row hot or cold aisle containment in any data center. Doors are available in standard sizes as well as custom sizes to fit under overhead obstructions or other sizing requirements. There are no obstructions on the floor of the aisle that could impede access of a person or trolley.

Customized Roof Panels (Black anodized Aluminum Extruded frame profiles with Clear transparent Fire retardant rigidULV-0 acrylic insert) to enclose the open top portion of the aisle with support taken from the false/actual ceiling.